Automation and robotic manufacturing applications

Sources:本站 | Release date:

2018-02-01

| Browsing volume:

Key words:自动化与机器人

One of the important application areas of automation technology is manufacturing. For many people, automation means manufacturing automation. In this article, the types of automation are defined and an example of an automation system used in manufacturing is described.

There are three types of automation in production: (1) fixed automation; (2) programmable automation; and (3) flexible automation.

Fixed automation, also known as "hard automation," refers to automated production facilities where the sequence of processing operations is configured by fixed equipment. In fact, programmed commands are included in the machine in the form of cams, gears, wires, and other hardware that are not easily converted from one product style to another. This automated form is characterized by high initial investment and high productivity. Therefore, it is suitable for products produced in large quantities. Examples of fixed automation include processing transmission lines in the automotive industry, automated assembly machines, and certain chemical processes.

Programmable automation is an automated form of mass production. The volume production of these products ranges from tens to thousands. For each new batch, the production equipment needs to be reprogrammed and replaced to accommodate the new product style. This reprogramming and conversion takes time to complete and has a period of non-productive time, then a production run for each new batch. Programmable automation typically has lower productivity than fixed automation because the device is designed to facilitate product conversion rather than product specialization. CNC machine tools are a good example of programmable automation. The program is coded in computer memory for each different product type and the machine tool is controlled by a computer program. Industrial robots are another example.

Flexible automation is an extension of programmable automation. The downside of programmable automation is the need to re-plan and change the time it takes for each new batch of production equipment. This is a waste of production time, which is expensive. In flexible automation, various products are limited enough to allow for very fast and automatic conversion of the device. Device reprogramming in flexible automation is done offline; that is, programming is done on a computer terminal without using the production device itself. Therefore, it is not necessary to group the same products; instead, a mixture of different products can be produced one by one.

Please indicate the source of the reprint(Automation and robotic manufacturing applications:/companynews/422)

Relevant articles

Related products

-

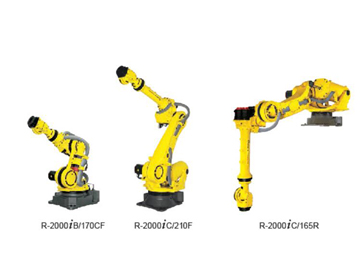

FANUC robot comprehensive sample

-

ABB

-

Painting robot

-

Palletizing robot, other

-

Large robot

-

Medium robot

-

Arc welding robot, small and medium robot

-

FANUC fist robot, mini robot

-

Collaborative robot

-

Double material detection