Robotics in the food and beverage industry

Sources:本站 | Release date:

2018-08-29

| Browsing volume:

Key words:食品机器人,饮料机器人

As government regulations become more stringent, retailers' demands continue to increase, and competition becomes more intense, the demand for robots is unprecedented for the success of the food and beverage industry.

Robots help prevent food contamination

With the implementation of food safety regulations, the pollution problem in food supply has attracted more and more attention. Modern robots feature improved hygienic design, making them ideal for working in this clean environment. Smooth surfaces that are not susceptible to corrosion by cleaning chemicals, as well as tight seals that lock in contaminants, are just some of the safety-conscious design features.

SCARA (Selecting a compliant assembly robot) robot is commonly used for food processing. Their low cost, low footprint and high throughput rate are attractive to manufacturers who want to increase efficiency. According to PMMI, 48% of dairy processors indicated that they need processing equipment. As manufacturers seek to eliminate the pollution caused by human contact with food, more and more robots are being implemented in food processing.

Pick and pack robot

Because robots don't get tired of performing repetitive tasks, they are also an ideal solution for major packaging tasks such as bottle handling, bin picking, and pallet loading. The main driver behind the growing number of applications for primary packaging robots is the growing demand for more diverse packaging, packaging quantities and retail packaging.

Food packaging dominates the global retail industry with nearly 2 trillion units of sales per year, and beverage packaging ranks second with sales of more than 1 trillion units. By 2018, food and beverage manufacturers plan to increase robot usage on primary packaging lines to 22% (9% in 2013) and 8% (5% in 2013). This is because robots offer greater productivity, flexibility and efficiency on the primary packaging line.

Robot palletizing system

Once packaged, the robot is used to prepare the transport product. Two of the three manufacturing locations have palletizing robots installed, plan to install more robots, or plan to add them to palletizing operations in the future. A wide variety of arm end tools can handle everything from a single product to a complete line, and even handle the entire product layer according to customer needs. The use of palletizing robots results in higher line efficiency, greater flexibility and cost savings.

As costs continue to decline and capabilities continue to increase, industrial robots will be a key driver of manufacturers' desire to remain competitive in the food and beverage industry.

Please indicate the source of the reprint(Robotics in the food and beverage industry:/companynews/422)

Relevant articles

Related products

-

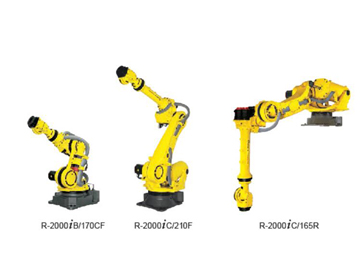

FANUC robot comprehensive sample

-

ABB

-

Painting robot

-

Palletizing robot, other

-

Large robot

-

Medium robot

-

Arc welding robot, small and medium robot

-

FANUC fist robot, mini robot

-

Collaborative robot

-

Double material detection