Industrial robots offer 4 ways to automate packaging automation

Sources:本站 | Release date:

2018-07-16

| Browsing volume:

Key words:工业机器人包装自动化

The current manufacturing landscape is affected by rapid changes in demand and requires efficient custom technology. That's why flexible automation is critical for companies looking to stay competitive and grow their business.

Flexibility is a key feature in the manufacturing environment as production run time between SKUs and packaging materials is reduced, especially in packaging automation. This is why industrial robot systems are a good choice. They provide a highly adaptable and effective solution when changes occur. Let's take a look at some of these scenarios.

Frequent replacement of packaging materials

There are multiple drivers behind the need for flexibility, and robots can help defend them in a variety of ways. Marketing efforts often change packaging materials, requiring existing automation to handle different primary and secondary packaging materials. To solve this problem, we often design a robotic end tool that can handle a variety of products and/or tray modes. This allows customers to better respond to potential modifications in their products or processes and help them stay productive.

Product line update

With simple program changes or different arm tools, robotics can be easily applied to new applications. For example, if you remove a product line that the robot is serving, the robot may be reused elsewhere in the facility to perform different functions. In contrast, most traditional devices offer limited reusability without major changes.

Fragile product or packaging

Many companies are also focusing on green initiatives, which typically reduce the amount of packaging material and require automation to handle the product as gently as possible to avoid damage. Each end of the arm tool we design and manufacture is created with the product in mind to ensure gentle operation. Each tool is customized to meet your specific product requirements.

Unique work unit footprint

In addition to providing the flexibility to handle a wide range of packaging materials and perform a variety of applications, Robotic Automation also allows you to customize the work cell to fit your available space. Often, traditional or "hard automation" solutions are only available for standard configurations with a large footprint. However, for robotics, you can often take advantage of the flexibility that robots provide and use them in layouts that are not possible with traditional devices.

Flexible robotic automation makes it easy for companies to overcome these and other obstacles, so the next time you identify a new packaging project, plan for the future and let us consider the flexibility in design. This way, you can be sure that your system is adaptable and ready for any changes that may come in the future.

Please indicate the source of the reprint(Industrial robots offer 4 ways to automate packaging automation:/companynews/422)

Relevant articles

Related products

-

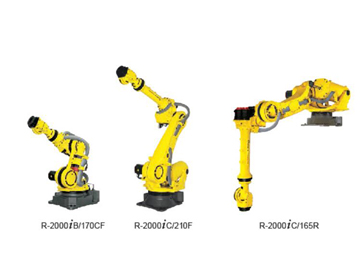

FANUC robot comprehensive sample

-

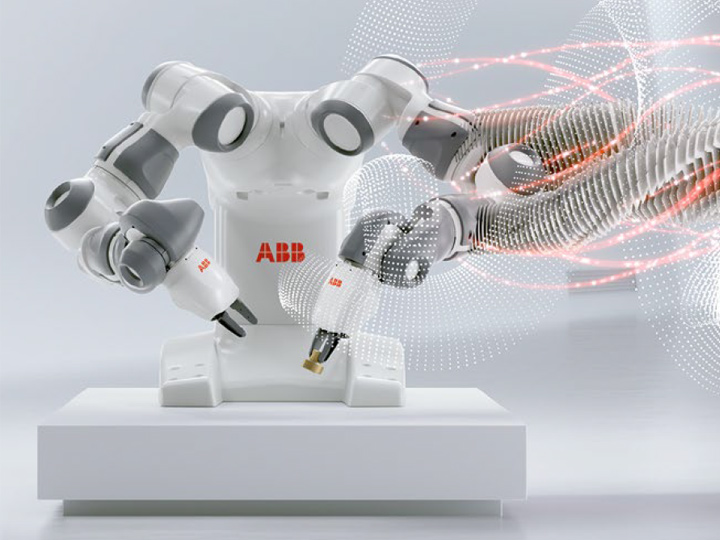

ABB

-

Painting robot

-

Palletizing robot, other

-

Large robot

-

Medium robot

-

Arc welding robot, small and medium robot

-

FANUC fist robot, mini robot

-

Collaborative robot

-

Double material detection