The application of automotive industrial robots makes human work easier

Sources:本站 | Release date:

2018-05-31

| Browsing volume:

Key words:汽车工业机器人工作更轻松

For many years, the automotive industry has been using robots in different applications. The advent of the first industrial robots of the 1960s brought many changes to the manufacturing industry, including the automotive industry.

In modern times, the industry pursues a more efficient, precise and flexible production line, so robots are needed. In order to make human work easier, there are many improvements in the production line. The introduction of automotive robots is one of the successful ways in which the industry has succeeded in doing this.

The following are common robot applications in the automotive industry.

Robot vision

The robotic arm is controlled by the eye by placing the camera and laser on the wrist of the robot. As a result, the robot can see where it is necessary to install the car parts in the body component.

The robot can achieve precision when installing door panels, windshields and fenders, and other body parts. Today, automotive robots are able to place the appropriate offset when installing parts. In this way, the robot can use different installation procedures when assembling parts to avoid changes during production. The accuracy provided by the application reduces the gap between the parts, which reduces the noise generated by the wind.

Cooperative robot

The collaboration between robots and robots is also a common application of robotics in the automotive industry. In some automotive plants, welding lines are one of the common areas where robots and robots work together. For example, in many different workstations where the processing robot and the welding robot cooperate, it is possible to have the same type of robot.

Some robots can lay out panels, while others can perform welding operations. Through this collaboration, some car manufacturers have found that robotic line collaboration can perform at least 4000 body welding jobs in cycles of only 86 seconds, including the time it takes to transfer operations.

Robotic hand

Just as the automotive industry makes greater use of industrial robots on production lines, it also requires labor in the finishing phase of the completion process. Most manufacturing is done using a robotic robotic arm, and most assembly tasks are still done manually, with tasks such as operation and wiring still being done by humans.

Create robotic arms to make it easier for humans to work. Robotic arms are used in the automotive industry to reduce the pressure on humans due to repetitive tasks. For example, robotic arm technology can provide workers with 10 pounds of grip. These arm grippers feature mounted sensors, simulated nerves, actuators, tendons and muscles to help reduce fatigue while increasing manual flexibility.

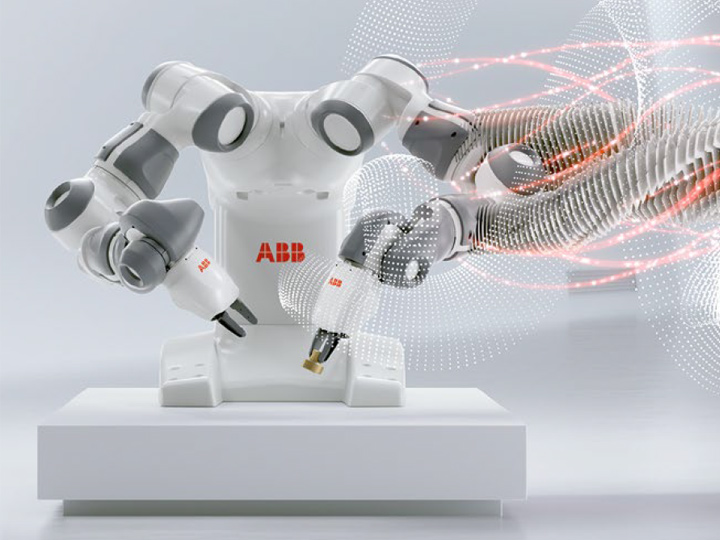

Collaborative robot

Cobots are commonplace in most manufacturing plants. The automotive industry is one of the places where collaborative robots are often used. The need for collaborative robots in manufacturing plants means replacing humans in performing repetitive tasks that pose a high risk of injury. Car collaboration robots are used for the assembly of the doors. These robots help to accurately install door sealants because they keep the water and sound of the car. Introducing collaborative automotive robots with people increases productivity and adds value to the workplace.

Spraying work

Although the application of robots to automotive painting is not new, it is still an important aspect of automotive manufacturing. The need for painting robots ensures that the car is painted to the desired level, which is sometimes difficult to accomplish with a human painter. In addition, depending on the size of the car, it is often easier for car manufacturers to use robots to do the job. This ensures that the job is completed in the shortest possible time and is achieved through the entire production line.

Please indicate the source of the reprint(The application of automotive industrial robots makes human work easier:/companynews/422)

Relevant articles

Related products

-

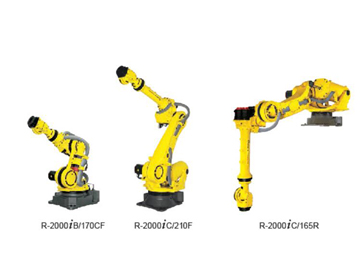

FANUC robot comprehensive sample

-

ABB

-

Painting robot

-

Palletizing robot, other

-

Large robot

-

Medium robot

-

Arc welding robot, small and medium robot

-

FANUC fist robot, mini robot

-

Collaborative robot

-

Double material detection