Robotic automatic welding production line is divided into spot welding and arc welding. It is mainly used in the production of automobiles, airplanes, electronics, instruments and daily necessities.

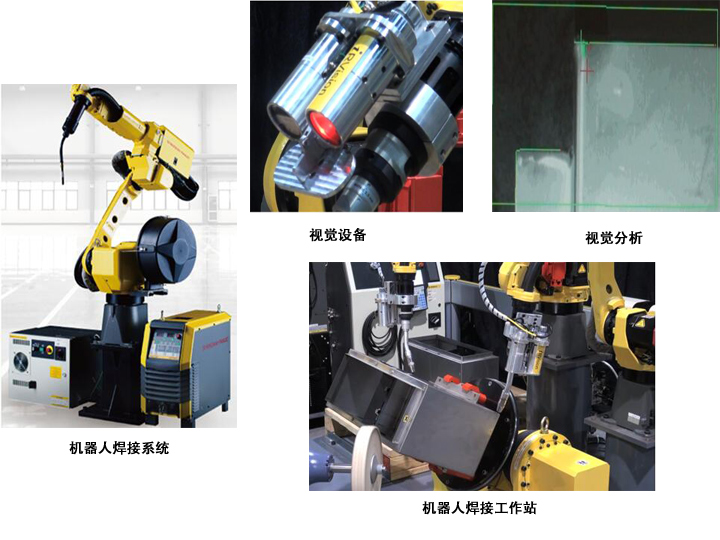

Core composition: two parts of robot and professional process welding equipment. Among them, the robot is composed of the robot body and the control cabinet (hardware and software); and the welding equipment, such as arc welding and spot welding, is composed of welding power source (including its control system), wire feeder (arc welding), welding torch ( Pliers and other parts. For smart workstations, there are sensing systems such as laser or camera sensors and their controls.

Features: Stabilize and improve the quality of welding, ensure its uniformity; Improve the working conditions of workers, can work in a harmful environment for a long time; Improve productivity, continuous production 24 hours a day; Reduce the requirements for workers' operating technology; Shorten product replacement Cycle, reduce the corresponding investment equipment; can achieve batch product welding automation; save floor space.

Key technology

Welding robot system optimization integration, system simulation and off-line programming, coordinated control of multi-robot and positioner, visual inspection, tooling positioning.

机器人自动化焊接生产线